When it comes to maintaining the efficiency and longevity of your electric motors, one crucial component that often goes unnoticed are the motor brushes. These small but mighty pieces play a significant role in ensuring the smooth operation of your equipment.

What are Motor Brushes?

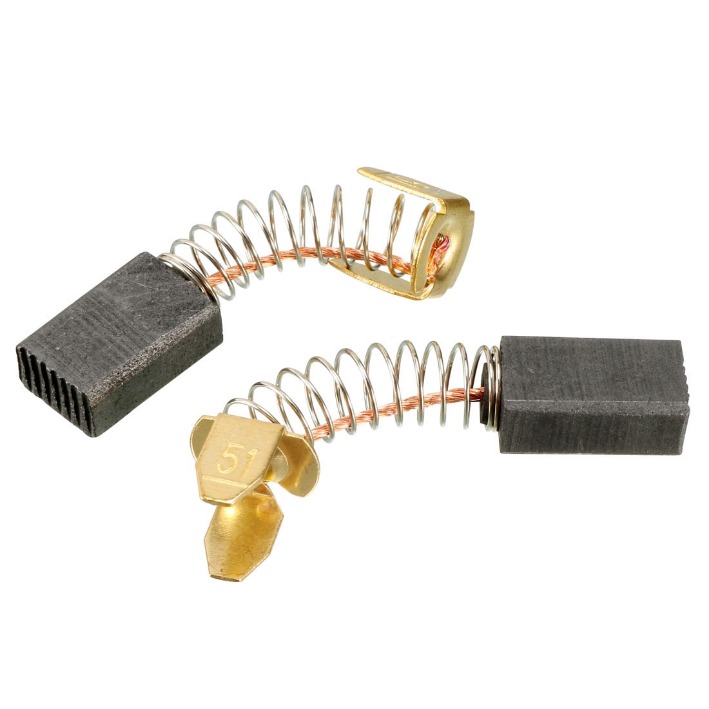

Motor brushes are essential components of electric motors that conduct electrical current between stationary wires (stator) and moving parts (rotor). They are typically made of carbon or graphite and are designed to withstand constant friction and wear.

Why are Motor Brushes Important?

- Conductivity: Motor brushes are responsible for transferring electrical current to the motor’s rotating components, enabling them to function properly.

- Friction Reduction: The brushes help reduce friction between the moving and stationary parts of the motor, preventing damage and ensuring smooth operation.

- Efficiency: By maintaining proper contact between the brushes and the motor’s components, efficiency is maximized, leading to improved performance and energy savings.

When to Replace Motor Brushes?

As motor brushes wear down over time due to constant use, it is essential to monitor their condition regularly. Here are some signs that indicate it may be time to replace your motor brushes:

- Decreased Performance: If you notice a decrease in the motor’s power output or efficiency, it could be due to worn-out brushes.

- Excessive Sparking: Sparking between the brushes and the motor’s components is a sign of poor contact and indicates the need for replacement.

- Noise: Unusual noises or vibrations coming from the motor can be a result of worn or damaged brushes.

Where to Find Quality Motor Brushes?

When it comes to finding reliable and durable motor brushes, it is essential to choose a reputable supplier known for their quality products. Look for suppliers who offer:

- High-Quality Materials: Opt for brushes made from premium carbon or graphite materials for longevity and efficiency.

- Customized Solutions: Choose suppliers who can provide custom brushes tailored to your specific motor requirements.

- Excellent Customer Support: Ensure the supplier offers excellent customer service and technical support for any queries or concerns.

Read more about Carbon brushes for power tools here.

By prioritizing the maintenance and replacement of motor brushes, you can ensure the optimal performance and durability of your electric motors. Invest in quality brushes today and keep your equipment running smoothly for years to come.