In the realm of manufacturing, precision and efficiency are paramount. Companies are constantly seeking innovative ways to improve their production processes, reduce costs, and enhance their product quality. One such groundbreaking method that has gained immense popularity in recent years is plastic injection molding services.

Read more about china plastic molding company here.

The Basics of Plastic Injection Molding

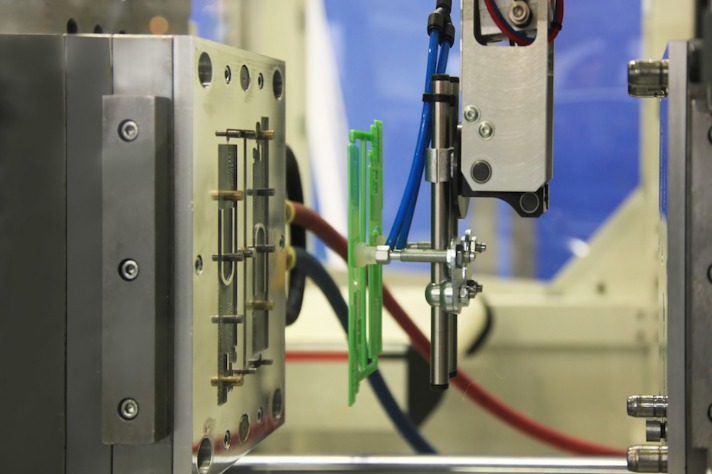

Plastic injection molding is a manufacturing process in which molten plastic material is injected into a mold cavity, where it cools and solidifies to form the desired part or product. This technique is widely used across various industries due to its versatility, speed, and cost-effectiveness.

The Advantages of Plastic Injection Molding Services

One of the key advantages of plastic injection molding services is the ability to create complex and intricate shapes with high precision. This makes it an ideal choice for producing a wide range of products, from medical devices and automotive components to consumer goods and electronics.

Additionally, plastic injection molding offers fast production cycles, allowing companies to scale up their manufacturing operations quickly and efficiently. The process also generates minimal waste, as any excess plastic material can be recycled and reused, making it an environmentally friendly option.

Choosing the Right Plastic Injection Molding Partner

When seeking plastic injection molding services, it is essential to partner with a reputable and experienced manufacturer. Look for a company that utilizes advanced technology and techniques to ensure the highest quality standards and precision in their products.

Moreover, consider a manufacturer that offers customization options and can work closely with you to develop the perfect solution for your specific needs. By collaborating with the right partner, you can streamline your production process, reduce costs, and ultimately achieve success in the competitive manufacturing industry.

In conclusion, plastic injection molding services have revolutionized the manufacturing sector, offering unmatched efficiency, precision, and versatility. By harnessing the power of this innovative technique, businesses can elevate their production capabilities and achieve remarkable results.